Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

How to Choose NDIR Refrigerant Sensors?

Jun 21,2023

NDIR refrigerant sensor is a kind of refrigerant sensor. In addition, there are refrigerant sensors based on semiconductor, thermal conductivity, and ultrasonic waves.

Refrigeration systems are inseparable from many industries, such as HVAC, industrial processes, air conditioning, refrigeration equipment, etc. Continuous monitoring of the refrigerant is very important to ensure the proper operation of the refrigeration system. This is why NDIR refrigerant sensors are becoming more and more widespread. They are closely related to our lives.

What is an NDIR refrigerant sensor?

NDIR stands for Non-Dispersive Infrared, NDIR refrigerant sensor is a detection element that measures the amount of refrigerant in a refrigeration system. It works by using infrared light to detect the amount of refrigerant in the air. The refrigerant sensor is generally connected with the main controller of the air conditioner and sends information to the main controller. Customers can make the main controller issue commands such as alarm or blowing diffusion according to application requirements.

What refrigerant gases can the NDIR refrigerant sensor detect?

R290 is a natural new environmentally friendly refrigerant directly obtained from liquefied gas. It has zero damage to the ozone layer and will not cause the "greenhouse effect". But it also has disadvantages. It belongs to the A3 class of flammable and explosive refrigerants, which has great safety risks. The concentration of R290 in the air reaches 2.1%~9.5%. It is very likely to burn or explode when it encounters an open flame, high temperature source, or static electricity!

R454B is a mildly flammable low global warming potential (GWP) hydrofluoroolefin-based refrigerant. The composition does not contain Freon, which can greatly reduce the harm and damage to the atmosphere, and is not easy to decompose and oxidize. Can replace R410a in direct expansion air conditioners, chillers and heat pump applications.

R32 is relatively more environmentally friendly and energy-saving, it will not damage the ozone layer, nor will it aggravate the "greenhouse effect". But it has safety and technical challenges: it requires high-standard equipment and plumbing, as well as high-level air-conditioning installers. It belongs to A2 flammable and explosive refrigerant, which is dangerous! If the refrigerant leaks and the concentration of R32 in the air reaches 15%~31%, it is very likely to cause combustion or explosion once it encounters an open flame!

R134a is the most widely used medium and low temperature environmentally friendly refrigerant. It can be used in most fields, including: refrigerators, freezers, water dispensers, car air conditioners, central air conditioners, dehumidifiers, cold storage, commercial refrigeration, ice water machines, ice cream machines, refrigeration condensing units and other refrigeration equipment.

What are the communication methods of ndir refrigerant sensor?

When the concentration of refrigerant is greater than the actual limit specified in the standard, the refrigerant detector needs to drive an alarm to alarm, and if the computer room has emergency mechanical ventilation equipment, it will also be activated. This ensures a safe working environment.

Winsen refrigerant sensor has various communication methods, such as 485, UART, PWM. For the existing ndir refrigerant sensor, the standard product is equipped with 485 communication mode. If you need to configure other communication modes, you can contact us for customization.

How about Winsen's NDIR refrigerant sensor?

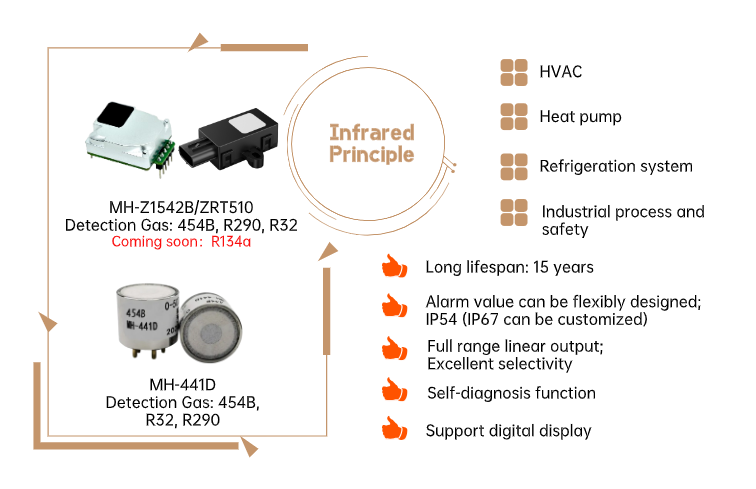

Winsen currently has 3 infrared NDIR refrigerant sensors. The average life expectancy is ≥15 years. The alarm value can be flexibly designed. Meet the requirements of digital display. In addition, the average current of our refrigerant sensor is <70mA, which can keep the air conditioner/heat pump at the green level of primary energy consumption.

Among them, ZRT510 is a refrigerant gas sensor module with self-diagnosis function. The lowest temperature the MH-Z1542B can reach is -20°C. MH-441D is mainly used in commercial central air-conditioning and cold storage.

Where is the best location to install the infrared refrigerant sensor detector?

The location selection of the refrigerant sensor detector is firstly related to the type of refrigerant. Second, the detector should be placed in a place where leaking refrigerant will accumulate. At least one refrigerant sensor detector should be installed in each machine room or use space, and special authorized personnel can enter for inspection or replacement. If the refrigerant is heavier than air, install it in the lowest area of the ground, and if the refrigerant is lighter than air, install it at the highest point.

Most ndir refrigerant sensors will be installed next to the evaporator of the air conditioner. Although the evaporator will have condensed water and dust, IP54 can basically protect the sensor, and the highest IP67 can be customized. A heating resistor can also be added to the sensor to prevent condensation from adhering to the sensor housing, but doing so will increase the power consumption of the sensor. We recommend that customers choose the installation location and whether to choose the upgraded ndir refrigerant sensor according to your actual application scenarios and needs.

What is the role of NDIR refrigerant sensor detectors in refrigeration systems?

NDIR refrigerant sensor detectors are an essential part of helping refrigeration systems run properly. It helps regulate refrigerant levels, improving energy efficiency, system performance and safety.

Improve energy efficiency: NDIR refrigerant sensor detector can reduce energy consumption by judging the current refrigerant concentration and adjusting the refrigerant content in the system. Doing so reduces the workload of the compressor and reduces costs.

Better system performance: NDIR refrigerant sensor detector can detect equipment failure in time, reduce downtime and improve system performance.

Increased safety: NDIR refrigerant sensor detectors detect refrigerant leaks that may be hazardous to human health. This helps keep workers safe and prevents environmental damage.