Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

MEMS Integrated Gas Sensor GM-202B

Summary:

MEMS smoke gas sensor is using MEMS micro-fabrication hot plate on a Si substrate base, gas-sensitive materials used in the clean air with low conductivity metal oxide semiconductor material. When the sensor exposed to gas atmosphere, the conductivity is changing as the detected gas concentration in the air. The higher the concentration of the gas, the higher the conductivity. Use simple circuit can convert the change of conductivity of the gas concentration corresponding to the output signal.

Feature:

* MEMS technology, Strong construction

* Good shock resistance

* Small sizes and low power consumption

* Fast response and resume

* Simple drive circuit, Long lifespan

APPLICATION

The combustible gas alarm is an alarm device for detecting gas leakage. The component that reacts to the combustible gas is a gas sensor, and the response signal is converted into an electrical signal through the circuit board. When the combustible gas in the air reaches a certain concentration value, the alarm will alarm. The high-end household combustible gas alarm can automatically start the exhaust equipment and close the gas pipeline valve at the same time. A wireless transmission device can be installed inside the gas alarm to realize overall monitoring and network alarm to ensure the safety of everyone's life and property.

Formaldehyde detector is an instrument for detecting formaldehyde. Generally, semiconductor sensors and electrochemical sensors are used to realize the rapid semi-quantification of formaldehyde in indoor air on the spot, which is characterized by simple structure, small size, intuitive,easy to carry and use.

Didn't Find Your Tarket Application?

Winsen offers tailor-made gas sensor solutions for your industry

PARAMETER

Technical Data Sheet

| Part No. | GM-202B | ||

| Sensor Type | MEMS | ||

| Standard Encapsulation | Ceramic | ||

| Detection Gas | CH4, C3H8 &etc. | ||

| Detection Range | 1~5000ppm (C3H8) | ||

| Standard Circuit Conditions | Loop Voltage | VC | ≤24V DC |

| Heater Voltage | VH | 2.5V±0.1V AC or DC | |

| Load Resistance | RL | Adjustable | |

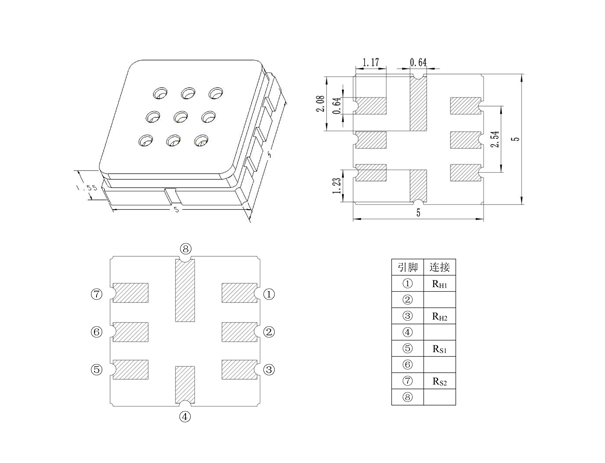

| Sensor character under standard test conditions | Heater Resistance | RH | 80Ω±20Ω(room temperature) |

| Heater consumption | PH | ≤50mW | |

| sensitive materials resistance | RS | 1KΩ~30KΩ(in 50ppm C3H8) | |

| Sensitivity | S | R0(in air)/Rs(in 5000ppmCH4)≥1.5 | |

| Concentration Slope | α | ≤0.6(R100ppm/R30ppmC3H8) | |

| Standard test conditions | Temp. Humidity | 20℃±2℃;55%±5%RH | |

| Standard test circuit | VH:2.5V±0.1V;VC :5.0V±0.1V | ||

Free Guide! Learn the Parameter Differences of Similar Sensors

Wondering how to find the most suitable one for you out of so many sensors? Download our free guide to learn the comparison table of technical parameters.

RELATED PRODUCTS

As a pioneer in gas sensor based solutions with the advanced processes, technologies and products, Winsen offers a wide range of gas sensors:

RELATED PRODUCTS

As a pioneer in gas sensor based solutions with the advanced processes, technologies and products, Winsen offers a wide range of gas sensors:

WHY CHOOSE WINSEN

Professional and Trustworthy

Brand Precipitation

Focus on Sensor Field

National Patents

International Advanced Technology

Detection Objects

More Than 300 Kinds

Production Process

Excellence Products

Provide 60+ Countries with Solutions

Serve the Global Market

Cooperate with 300+ well-known Enterprises

More Customer’s Choice

How to choose the right sensor for your project?

We have 17 sensor series, 200+ categories, and 300+ detection objects for gas detection. Such as CO, CO2, VOC, PM2.5, CH4, LPG and so on. In particular, we also have MEMS sensors. According to your industry application, gas principle, power consumption, accuracy, and range requirements, and we can select a specific model for you. You can also use the product filter below to choose a suitable product, or choose online serivce.

Here you can learn about the selection guide, common technical problems, packaging, transportation, MOQ, delivery time, etc.

What is the Difference Between Semiconductor Sensors and Electrochemical Sensors?

What Are the Precautions for Manual Soldering of Semiconductor Sensors?

Can Wave Soldering Be Used for Semiconductor Sensors?